Introduction of STG Ampute Aluminium alloy explosion-proof ball

The barrier explosion-proof materials produced by our company is a special aluminum alloy foil made by hot rolling process. It changes the mechanical properties of the material and is cut and stretched to form a cylinder or spheroid with a high-porosity network structure. This materials can effectively solve the problem of breakage during long-term use, and fundamentally solve the problem of blockage of pumps, meters, valves and various oil circuit systems. The material is widely used in buried storage tanks, hazardous chemicals transport vehicles, oil tankers, military equipment and national energy strategic reserve stations.

Domestic customers all over the country, such as Beijing, Shandong, Xinjiang, Jiangsu, Guangdong, Guangxi, Shaanxi, Sichuan, etc. The products are also sold overseas to many countries, such as Russia, Kyrgyzstan, Australia, Norway, etc.

Product safety

Protect the safety of inflammable and explosive liquid and gaseous hazardous chemical storage and transportation containers and devices, and effectively inhibit the explosion of hazardous chemical media (including gasoline, diesel, methanol, liquefied petroleum gas, etc.) in the event of open flame, electrostatic spark, welding, shooting, collision, wrong operation and other accidents.

A storage tank container equipped with a barrier explosion-proof material, once it encounters an open flame burning, the flame height of the burning is reduced to about one-thirtieth of the original, which is conducive to extinguishing the fire.New generation of product advantages

Better material propertiesMain products and features

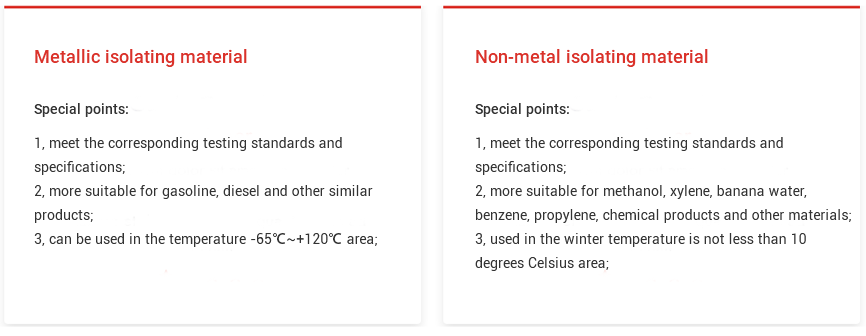

Isolation material characteristics

It can protect the storage and transportation of flammable and explosive liquid and gaseous dangerous chemicals, and effectively prevent the explosion of gasoline, diesel, chemicals and other substances in accidental circumstances.Energy saving and emission reduction, effectively inhibit oil and gas volatilization, reduce oil consumption, reduce environmental pollution.

Main specifications

|

Raw material specifications |

|

| Type of material | Aluminium band, blank as rolled, smooth, expanded |

| Thickness Tolerance | +0.005mm |

| Tensile Strength | 1.8-230N/mm2 |

| Elongation | 2%-3% |

| Thermal Conductivity | 155-195W/m*k |

| Surface | Clean, smooth as rolled |

| Material Thickness | 0.068mm |

| Specific Weight | 2.67g/cm3 |

| Weight | 9 g/ball |

| Lifetime | Approx. 30 years |

| Temperature Range | -80'c-+550℃ |

| Mesh material specifications | |

| Height Of Mesh | 2.4mm±0.2 |

| Aluminum foil width | 650mm |

| Standard | AQ/T 3001-2021 |

| Ball material specifications | |

| Ball Diameter | 6cm |

| The number of balls per cube | 5000 |

| Weight per cubic ball | 45kg-46kg |

| Shipping information | 60-foot standard container, can hold 50-55 cubic meters |

| Packing size | 1070*580*560mm |

| Customs code | 7616999000 |

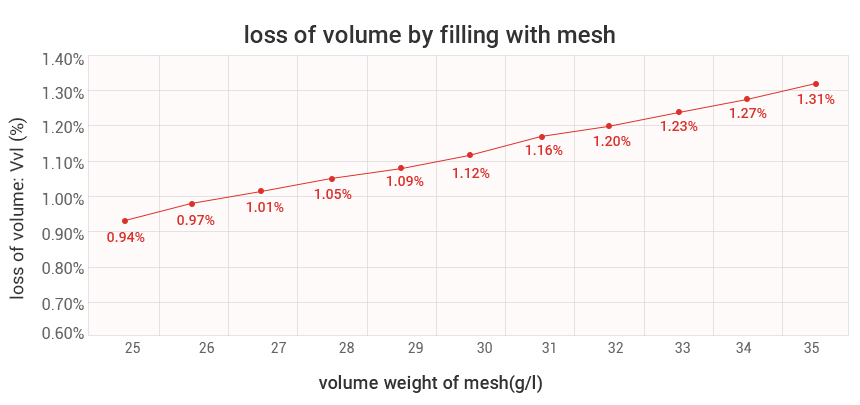

Specific weight of aluminium band:GAW 2670(g/l)

Vvl=(GMW /GAW)*100%

| Gmw(gl) | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 |

| Vvl | 0.94% | 0.97% | 1.01% | 1.05% | 1.09% | 1.12% | 1.16% | 1.20% | 1.23% | 1.27% | 1.31% |

Compatibility to Fuel

Abstract of test report issued byChinese People's Liberation Army Oil and Oil Equipment Test Center

Oil sample: No.90 car gasoline, No.-10 military diesel, No.3 jet fuel

Container: Metal can with epoxy resin printing in the wall, 4L

Conditions: Running test by 5000km, four weeks of accelerated storage test under 43'c

Test result:

- AMPUTE doesn't affect oil combustion property.

- AMPUTE doesn't affect oil low temperature property.

- AMPUTE slightly affects the oil invariability of long time storage, but it is not obvious.

- There is no effect on the generation of active sulfur in oil, namely installing AMPUTE explosion prevention system doesn't change copper sheet corrosion rate.

- There is not any change on the surface of AMPUTE and there is no fractured and womnmaterial in the metal can.

Applications

1. Used in gas station buried oil storage(gas) tank The series of products for barrier explosion-proof materials developed by the company is a high-techsafety and environmental protection product that is safe and explosion-proof. It does not pollute the environment and groundwater resources. It is widely used in urban centers, large parking, highways, towns and rural areas.

| Characteristics | Possible application | Application example |

|

Better material properties

Multi-variety design

Adapt to more demanding conditions of use

Easier installation and maintenance

|

Protection of military and civilian mobile fuel truck and gas station

Protection of onshore and offshore helideck

|

Too many,please see customer excerpt

Bayards Dintelmond BV The Netherlands

|

| Structural support for fuel tanks of military tank and fighting canoe | Nanjing Military Area Command Engineering and Scientific Research Academy | |

| Reduce approx.80% of Swash-effect on fuel in the oil tank. |

Shanghai naval base

Chinese People's Armed Police Force,Shanghai Contingent

|

|

| Protect LNG, LPG bottles and tanks | ||

| Thermal discharge of fuel in tank | Please see customer excerpt | |

| Chemical field: benzene, propylene, methanol, banana water, xylene | A chemical industry park in Shandong province |

Cleaning the storage tank by using AMPUTE abluent couldprevent combustion, explosion and “three wastes".

Explosion-proof ball delivery process

AMPUTE installation in Storage Tank

Oil tank cleaning → Ventilation → AMPUTE installation → Completion → Closing cover and igniting test → Experts inspection and acceptance