Introduction of STG Ampute Skid-mounted fueling device

STG Ampute has evolved from years of research and development to become the premier aboveground mobile fuel station. STG Ampute is designed to prevent liquids overfilling, vapor volatiizing, oil tank exploding ensuring superior safety, environmental responsibility and unparalleled ife cycle value.

The patented explosion prevention system could protect the oil tank from explosion caused by open flame, static, welding, shot and colision.

. Tank over fill protection

. High and low level liquid sensing

. Direct reading volmetric gauging

. Vapor leakage detector in interstice

. Stage II vapor recovery system(OPW)

. Anti-static grounding device

Product feature

1, safe and explosion-proof

The double-wall storage tank is filled with barrier explosion-proof materials that meet national standards. Once an accident occurs, such as open fire, static electricity, gunfire, lightning strikes, etc., no explosion will occur and casualties can be avoided. At the same time, an automatic alarm control system is also set up to find abnormal conditions in time and carry out emergency treatment.

2. Energy conservation and emission reduction

The device is equipped with oil and gas recovery system, which inhibits and reduces oil volatilization and reduces air pollution.

3. Environmental protection standards

The device is equipped with oil leakage monitoring system, in case of oil and gas leakage, sound and light alarm to avoid pollution of soil and groundwater resources.

4. eliminate static electricity

The accumulation of static electricity generated in the process of oil filling and unloading is eliminated in time to avoid sparks and greatly improve safety.

5. Flexible configuration

According to the needs of users, different specifications of explosion-proof storage tanks can be configured, containing a variety of specifications of oil products, the selection of different functions of the tanker for flexible configuration.

6. diversified modeling

The appearance of the device can be personalized according to user requirements and environmental characteristics to meet the needs of customer image publicity.

7.cost-effective

Compared with traditional gas stations, the station construction time is short, as long as three days, as short as one day, less investment, quick effect.

8.good economy

The construction cost is low, the floor area is small (the maximum floor area is: 60 square meters), it can be moved easily according to needs, and the investment protection rate is high.

9. easy to install

The device can be lifted and transported as a whole, once in place, easy to install, simple and convenient.

10.easy to clean

The tank can be closed and cleaned at any time, which is safe, simple, fast and easy to maintain.

Application

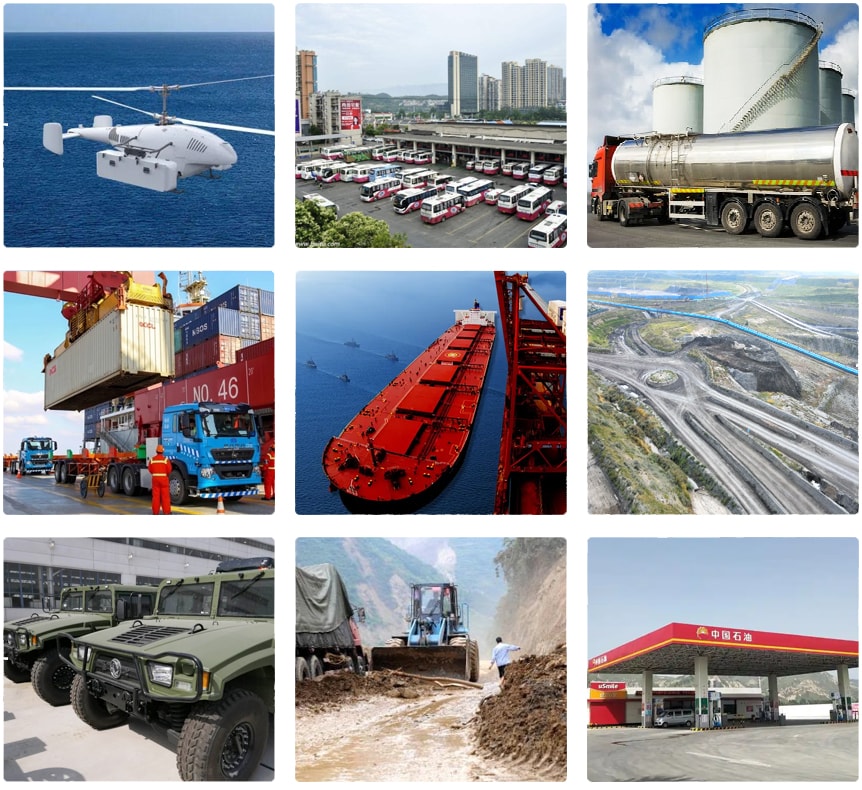

STG Ampute mobile fuel station could be applied to fixed or temporary field at urban central region, city community, airports, seaports, construction and freight yards, bus parking, expressway, exhibition center, countryside with a low density of traditional fuel station, also could be used for security forces -the army and police(provision of fuel in crisis areas) and in-house fuel station.

Sales network

Series Products

|

Capacity(liter) |

Dimension(mm) |

Weight(ton) |

|

10,000,single oil,one fuel dispenser |

6280*2000*2300 |

10 |

|

15,000,single oil,one fuel dispenser |

11000*1900*2400 |

11 |

|

20,000,double oils,one or two fuel dispenser |

10650*1980*2567 |

13 |

|

30,000,double oils,one or two fuel dispenser |

11840*2438*2900 |

18 |

Delivery process

Pre-construction Requirements

Before construction, mobile gas station operators must obtain the following qualifications:

-It is necessary to obtain local authorities for site allocation, building planning and district approval, etc.

. The following issues should be done: a) When choosing to build a gas station location, it should minimize the potential risks of gas station facilities to the safety of nearby residents, and should take into account the dangers that may be caused to nearby residents when an accident occurs at a gas station, and take relevant defense measures; b) Proximity to public ways; c) Proximity to waterways and other surface water; d) Near the freeway; e) Keep away from other dangerous facilities; f) Understand the location of utilities (including electricity, sewers) and related parameters near the gas station;

Pre-sale service

Help customers to determine the pre-sale plan: equipment selection, installation site survey, design plane installation layout, foundation infrastructure plan, power supply plan and other technical services.

To provide APT barrier explosion-proof skid refueling device performance, characteristics, safety specifications and other technical consulting services.

In-sale service

Help customers to transport, delivery to the designated location. Arrange professional and technical personnel to install and debug on site.

On-site free use, maintenance and maintenance training for customers.

Perfect customer service network, can provide customers with fast and convenient service.

After-sales service

After the equipment is put into operation during the warranty period, due to the quality problems caused by the product manufacturing process, our company free maintenance; Customer satisfaction will be called back after repair.

After the return visit, the information will be recorded in the user file. Make suggestions to improve the reasonable requirements of customers.

1. Oil tanker

2. Liquid level meter

3. Explosion-proof storage tank

4. Oil and gas, liquid level and automatic fire alarm system

5. Refueling pipeline system

6. Unload the oil piping system

7. Oil and gas recovery pipeline system

8. Clean the pipe system

9. Lightning and ESD protection system

10. Operation, maintenance and protection system

11. Oil leak detection system

12. Electrical control system

1.Safe and explosion-proof;

2. Energy conservation and emission reduction;

3. Environmental protection standards;

4. Eliminate static electricity;

5. Flexible configuration;

6. Diversified modeling;

7. High cost performance;

8. Good economy;

9. Easy to install;

10. Easy to clean.

Economic accounting: a 30 cubic skid refueling device, calculated by about 550,000, the average daily sales of oil products is about 8-10 tons, with a profit of 500 yuan per ton, the daily profit of 4000-5000 yuan, 150 days is about 600-750,000, half a year can be returned.

The whole machine warranty period is one year from the date of acceptance by both parties, APT barrier explosion-proof storage tank and barrier explosion-proof materials can be guaranteed for 20 years, the main parts warranty period of one year, lifetime warranty. Vulnerable accessories such as: lamps, door locks, valves, gaskets, belts, etc., are not within the scope of warranty; Other major accessories refer to the parts manual.

1. Before the construction of the station, our company will provide relevant drawings and photos of the station for customers to consult and guide the construction of the station, or assign engineers to survey the site where the skid is installed, and finally design the layout plan, foundation infrastructure plan and power supply plan for the user.

2, when installing, compared with traditional gas stations, the station construction time is short, as long as three days, as short as one day. One equipment only needs to be equipped with 1 or 2 refueling employees, and can be operated after simple operation training.

In the provincial and local fire departments and safety supervision departments can be filed (most of the provinces and cities, our company has done the record). Our company is responsible for providing equipment related information documents for the buyer to apply for approval in the local procedures, and our company will send someone to assist and guide the relevant procedures.

1. It can be used normally in hot, cold and plateau areas. In particular, the equipment is specially equipped with high altitude oil pump.

2, if there is no supporting power system and business room, our company can be equipped with generators, auxiliary business room. In cold areas, it can also be equipped with equipment heating control device, which can ensure the normal work and life of refueling employees.

1, double-wall storage tank structure, the inner tank is filled with barrier explosion-proof metal materials in line with national standards, once an accident, such as open fire, static electricity, shooting, lightning strikes, will not explode, can avoid casualties; At the same time, an automatic alarm control system is set up to detect abnormal conditions in time and carry out emergency treatment.

2. APT barrier explosion-proof skid refueling device has passed the test of China Special Equipment Testing Institute, and the test items include refueling with fire; Tank mouth ignition; Drilling and repair welding of oil tanks; Burn the tank with No. 0 diesel for one hour.

Due to the particularity of the process flow, operating procedures and laws and regulations of skid filling stations, skid filling stations should adopt different management modes according to the different service objects, which generally include:

1. Independent management mode. As the terminal extension function of the gas station, through negotiation with customers, under the condition of the partner's own and unified management of the fleet, the equipment installation site is provided, the skid-mounted refueling facilities and oil products are invested, and employees are sent to the vehicle parking place for refueling services.

2. Partner management. The oil supply contract shall be signed with the customer in the form of the refined oil sales agreement, and the partner shall entrust special personnel to manage it. We provide customers with skid-mounted equipment, and send people to supervise and maintain the equipment on a regular basis.

3. Develop and operate gas stations with independent business entities.